Resources

We have put together a mix of self help articles, video's and diagnostic tools. Please feel free to download and should you require any assistance we would be happy to help.

Start Small, Learn Fast: A Digital Leadership Blueprint

- Details

- Category: Resources

Advances in technology and cloud based software has made it easier than ever to collect and analyse shop floor data and use the results to guide the day to day routine. This creates a digital ecosystem which can deliver impressive gains.

This often reveals weaknesses in shop floor processes leading to significant changes in roles, task transfer and the development of new skills.

Organisations that do this well adopt a "Start Small, Learn Fast" approach, here is how they develop their Digital Leadership Blueprint to scale up the gains from what they learn by doing that.

Making Better Use of Data

- Details

- Category: Resources

In a world brimming with data and digital potential, organisations often find themselves at a crossroads. The challenge isn't just in collecting data, but in harnessing it to drive meaningful change and innovation to create a new Execution Model.

To truly leverage data, it is crucial to learn how to ask the right questions so that analysis can transform raw data into valuable insights. This process is about more than numbers; it's about:

- Understanding the causal factors behind the numbers and the decisions they can inform.

- Being in a role that is allowed to act on that information.

This last factor is important because making best use of the wider availability of quality information involves the delegation of accountabilities towards front line personnel. A shift which began with the use of Visual Management and now continues with Digitisation.

The TPM roadmap offers a structured approach to navigate these uncertain waters.

Can the Lean TPM Road Map Deliver Your Full Potential?

- Details

- Category: Resources

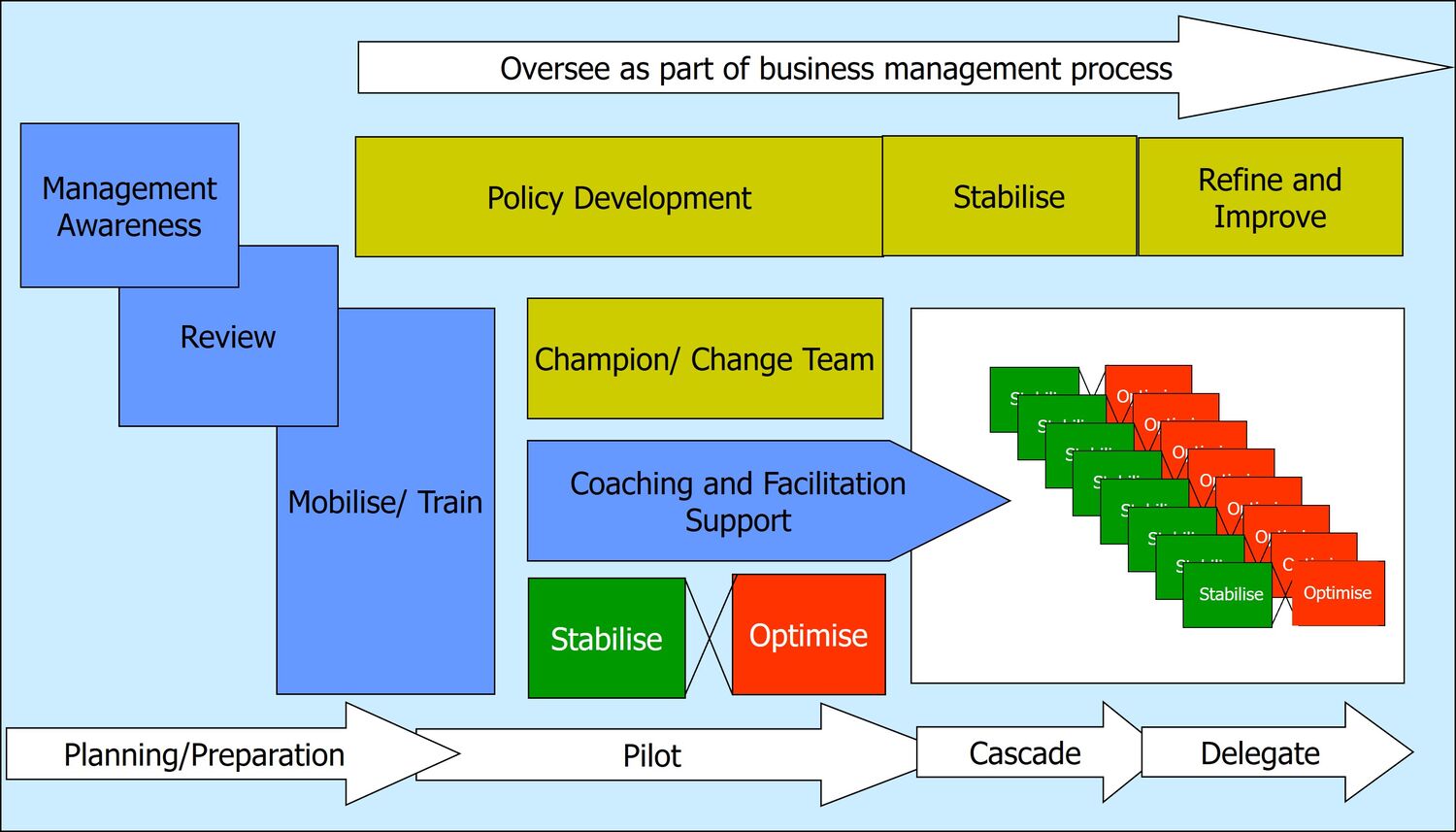

The LeanTPM Roadmap, developed over 30 years of practical application, provides an insight into how successful organisations deal with the multiple factors that interact to drive performance. Not just at any given moment but over months, years or even decades. Over that timescale, markets change, people move on, new people join, technology advances.

How do they do that?

Benchmark and Improve Your Improvement Process

- Details

- Category: Resources

Complete this short 10 question diagnostic to obtain a benchmark report of your current progress against the CI transitions of respected and award winning organisations on their journey to excellence.

You will also receive a confidential report setting out strengths and weaknesses as well as recommended next steps to progress towards industry leading performance.

Introducing Improvement Cycles

- Details

- Category: Resources

Making Improvement a Part of the Routine

A key part of the leaders role is to look beyond the day to day horizon to build on existing good practices and avoid past pitfalls with the aim of improving future performance.

That involves a mix of working sessions to understand causal factors and identify how to establish new standards and ways of working. The implementation of those enhancements requires training, coaching and feedback to develop skills and assure compliance. Here is how to do all of that as part of the routine.

Unlock The Power of TPM Centres of Excellence

- Details

- Category: Resources

Organisations that successfully deliver lasting improvement, invest time in creating Centres of Excellence by developing workforce capability to prevent the causes of failure, eliminate waste and improve workflow as part of the daily routine.

The Centre of Excellence approach is characterised by the goals that these successful organisations set, for example:

Releasing the Centre of Excellence Genie

- Details

- Category: Resources

Successful organisations are made up of multiple teams across organisational levels creating an improvement leader network to drive up performance.

These internal exist in all organisations but their presence is typically so informal and pervasive that their potential is rarely recognised.

Can Lean Maintenance Deliver Higher Added Value?

- Details

- Category: Resources

ean Maintenance transforms the maintenance role from fixing breakdowns to releasing the full potential of operational equipment and processes by delivering:

- Lean Asset Care covering preventive maintenance, inspection and servicing routines,

- Lean Execution covering standardisation, systemised workflows and engagement,

- Lean Systems covering stores, performance management and CMMS.

The gains include:

How to Release Lean Maintenance Added Value

- Details

- Category: Resources

Lean Maintenance guides the evolution of maintenance workflows to systematically reduce waste and non value adding activities,

That releases time to focus on enhancing process effectiveness and release the gains from advanced technology. The gains include improved capacity, resilience and flexibility that deliver real added value for manufacturing and process organisations.

Here is an overview of the Lean Maintenance implementation milestones.

Improving Capital Project Delivery

- Details

- Category: Resources

Every business needs to develop the capability to deliver projects well to respond to changes in market conditions and advances in technology. As almost all new ideas require testing to confirm proof of concept or to refine changes in work routines, Project Delivery is at the heart of any improvement process.

Unfortunately, studies show that only 1/3 of organisations achieve their planned level of return on investment.

The most common pitfalls occur...